CAMX continues to be one of the most valuable events in the composites calendar, bringing together innovators, suppliers, and manufacturers to discuss the technologies shaping the future of advanced materials. For ST Engineering MRAS, this year’s show was another opportunity to connect, share expertise, and explore what’s next in aerospace composites.

Connecting with the Industry

Connecting with the Industry

“CAMX is always a great opportunity to connect with suppliers and new potential suppliers in the industry,” said Tommy Acchione, Advanced Composite Material Leader. “It centralizes many conversations, which in turn fuels ideas.”

As a sponsor, MRAS participated in the First-Time Attendees Breakfast, engaging with newcomers to the industry and enjoying the energy and curiosity they brought to the event. CAMX added an interactive activity making it more than just a networking breakfast.

The event also gave MRAS exposure to a wide range of companies, including new players in material development. “We saw some exciting new faces this year, especially among smaller companies innovating in the material space,” Tommy noted.

MRAS’s Role in Composites Innovation

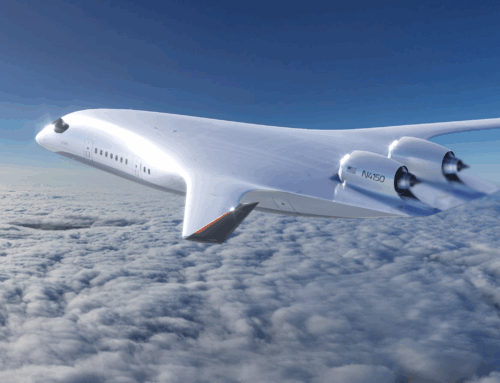

MRAS positions itself as an integration expert – able to take the full suite of tools available in the composites industry and optimize them for high-rate manufacturing.

“If we need to use a new material, we can test and certify it. If we need to use a new process, we have experts who can integrate it. If we need to use automation to fuel speed for customers, we have both machines and relationships to make that possible,” Tommy explained.

Ask the Expert: Driving Conversations on Composites

This year, MRAS experts Ben Wong, Matt Kurtz, and Josh Ma hosted a well-attended Ask the Expert session covering a range of key topics:

- Quick Turn Composite Tooling and Prototype Fabrication

- Additive Tooling for Composite Part Manufacture

- Composite Part/Material Development to Production

- Carbon Fiber/Epoxy Hand Layup and Automated Fiber Placement

- Material Test and Certification

- Automated Fiber Placement (AFP)

- High-Rate Aerospace Composite Manufacturing

- Composite Machining and Acoustic Drilling

One of the most impactful audience questions asked how MRAS’s learnings on high-rate manufacturing and automation could be applied to other composite processes.

“There is no one-size-fits-all approach,” Tommy explained. “Our recommendation is to start by mapping the process, automating and grouping the simple processes first, then moving into high-impact areas such as material management, ply and material kitting, and finally part fabrication.”

Technical Highlights

Technical Highlights

Quick Turn Tooling and Prototype Fabrication

MRAS has leveraged quick turn tooling for multiple programs – including Archer – using it to prototype demonstrators and trial new production concepts. Moving from prototype to production tooling requires a focus on robustness: adding hoist points, vacuum ports, and reinforcing areas that will experience higher stress in rate production.

Additive Tooling

Additive tooling is enabling MRAS to shorten the time from design to part and create a feedback loop into design. Using Stratasys-printed ABS masters splashed with SHD tooling prepreg, as well as large-format Thermwood PEI tooling from Additive Engineering Solutions, MRAS can produce tooling faster and at lower cost. Iterative builds also help avoid late-stage design issues.

Composite Part Development to Production

MRAS carefully interrogates all production challenges before releasing final drawings, gathering input from development teams and production troubleshooting teams to improve manufacturability. One key challenge is balancing time and budget pressures with design choices that could yield long-term benefits, such as material flexibility or interchangeable fasteners.

AFP and Hand Layup

To maximize AFP efficiency, parts should be designed for AFP from the start. MRAS typically applies AFP to large, smooth parts without tight radii, sometimes combining AFP with limited hand layup for damage tolerance. “We are working on future solutions that remove the need for woven products entirely,” Tommy said.

Material Test and Certification

Following CMH-17 guidelines and FAA regulations such as 14 CFR Part 25 and Part 33, MRAS ensures traceability and quality through NADCAP and ISO 9001-certified processes. Its in-house test lab enables complete material and part certification under one roof.

Automated Fiber Placement

MRAS has developed a robust AFP process capable of 24/7 production. One of the main barriers to wider AFP adoption is late-stage design handoff. MRAS is working to engage design engineers earlier to ensure parts are AFP-friendly from day one.

High-Rate Aerospace Composite Manufacturing

At MRAS, high rate is viewed in terms of the minimum TAKT time allowed to meet the production rates. This can vary depending on the customer’s needs, but for the highest production rate program, that means producing over 1000 units per year. Manufacturing technology development is driven by ensuring that TAKT time allotments are honored and achieved in the most efficient manner. An example of this was the transition from hand manufacturing to automated manufacturing, taking a 16-hour TAKT time down to under five hours. Design for manufacturing is critical to achieving these production rates.

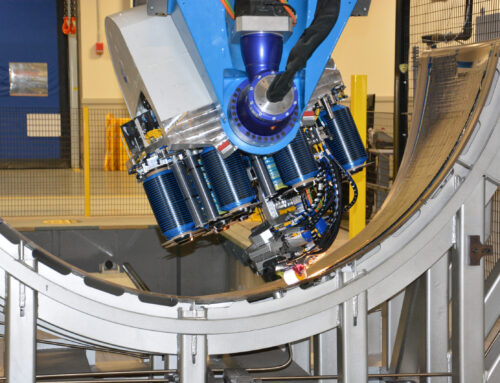

Composite Machining and Acoustic Drilling

MRAS uses 5-axis machining centers and multi-spindle acoustic drilling robots for trimming and perforating thrust reverser structures. Our extensive experience allows us to achieve on tolerance results that are void of any fiber breakout, surface finish issues, or delamination. This is achieved by innovative programming and control routines that ensure real-time tool life monitoring. The automation oversight assures tools are used effectively, eliminating premature cutter changes while producing superior finishes. New cutter technology is tested and introduced to the production lines, ensuring feeds and speeds continuously improve. All this is done with innovative dust collection systems that allow parts to move to the next production steps without needing additional processing.

Looking Ahead

MRAS’s participation at CAMX reinforces its commitment to collaboration and continuous improvement in aerospace composites manufacturing.