Automation

Revolutionizing Aerospace Manufacturing with Automation

MRAS is a pioneer in the aerospace industry, meticulously applying automation to enhance efficiency, precision, and quality across its manufacturing processes. Embracing the latest technological advancements, MRAS has established itself as a leader in automating complex aerospace components, delivering exceptional value to its aerospace OEM and Tier 1 partners.

Streamlining Assembly Operations

MRAS’s assembly automation solutions streamline the production process, reducing cycle times and improving overall throughput. The company utilizes sophisticated robotics, vision systems, and automated tracking systems to handle repetitive tasks with precision and efficiency. This automation not only enhances productivity but also reduces human error, ensuring the consistent delivery of high-quality components.

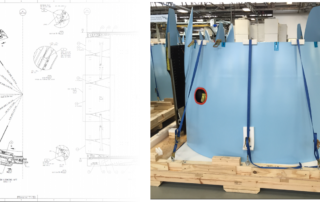

Automated Drilling and Machining

MRAS has invested heavily in automated drilling and machining systems, eliminating the need for manual operation and minimizing the risk of human error. These systems handle intricate cutting and drilling operations with precision, ensuring that components meet the stringent dimensional and surface finish requirements of the aerospace industry.

Advanced Robotics for Complex Structures

For the fabrication of complex aerospace structures, MRAS employs sophisticated robotic systems capable of handling materials ranging from metallic alloys to composite composites. These robots are programmed to perform precise welding, riveting, and fastening operations with minimal supervision, ensuring seamless integration of components and the creation of robust structures.

Automated Inspection and Quality Control

MRAS’s automated inspection and quality control systems play a crucial role in ensuring the consistent delivery of high-quality components. These systems utilize advanced vision technology and laser scanning to inspect components for dimensional accuracy, surface defects, and material variations. This comprehensive inspection process helps to identify and rectify any anomalies early in the manufacturing cycle, preventing costly rework and ensuring that only defect-free components reach the final assembly stages.

Real-time Monitoring and Data Analytics

MRAS integrates real-time monitoring and data analytics into its automation processes, providing valuable insights into production performance and quality control. This data-driven approach allows MRAS to proactively identify and address potential issues, optimize production parameters, and continuously improve overall manufacturing efficiency.

Partnering for Automation Excellence

MRAS collaborates closely with its aerospace partners to understand their specific automation needs and develop tailored solutions that align with their production processes and cost targets. The company’s expertise in automation technology and its deep understanding of aerospace manufacturing enables MRAS to provide comprehensive automation solutions that drive value and enhance competitiveness for its partners.

MRAS: Your Automation Trusted Partner

With its commitment to innovation and its vast experience in automation, MRAS is the trusted partner for aerospace OEMs and Tier 1 suppliers seeking to optimize their manufacturing processes and deliver exceptional value. From streamlined assembly operations to advanced robotics for complex structures, MRAS’s automation solutions are revolutionizing the aerospace industry, ensuring the consistent production of high-quality components that meet the demanding requirements of modern aircraft.