History

A History of MRAS

Operating from humble beginnings, MRAS soon became a global leader in aerospace technology. The history of MRAS is not just about machines and technology. It’s about the dedication of a company to consistently push industry boundaries.

Early Flight (1928-1940s):

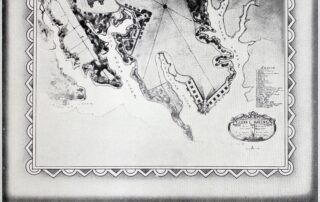

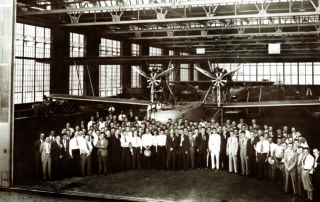

In 1929, visionary pioneer Glenn L. Martin opened a new aircraft manufacturing facility just outside of Baltimore in the small suburb of Middle River, Maryland. With proximity to Washington, D.C., and access to the Chesapeake Bay, railways and roads, this location provided everything his rapidly growing company required. Martin purchased 1,260 acres of land. Within a year, the Glenn L. Martin Company designed and constructed the first Baltimore-made airplane to take flight, marking the start of an era of remarkable creations.

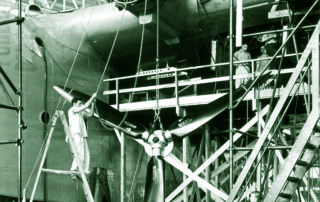

The 1930s saw a flurry of activity. From the world’s first practical intercontinental airliner, the China Clipper, to the first streamlines bomber, the Martin B-10, the company’s engineers were constantly redefining the limits of aircraft design. The Glenn L. Martin company produced hundreds of aircrafts, exporting many around to world to countries such as Russia, China, Argentina and the Netherlands.

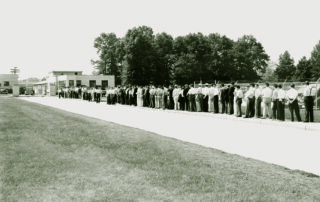

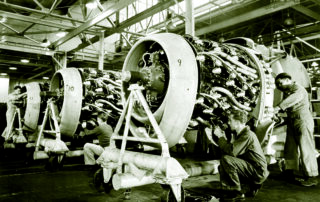

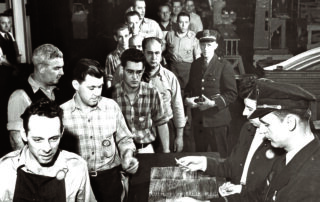

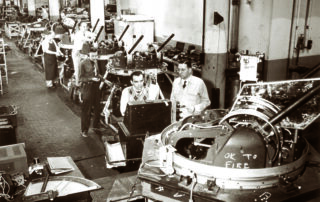

With the onset of World War II, the Baltimore facility transformed into a hive of activity. The Glenn L. Martin Company saw a quick growth in demand and so welcomed a mass influx of workers to cope. Two additional facilities were built purely for the production of B-26 Marauders. By the end of the 1940s, the company was also producing guided missiles and rockets. The Middle River site was now made up of multiple facility buildings, an airfield, passenger terminal and six hangers.

Embracing the Space Age (1950s-1960s):

During the 1950s, the Glenn L. Martin company had begun creating a line of commercial airliners. Martin also added to the company’s military products, designing the O5M Martil patrol boat and the P6M SeaMaster.

In 1961, the Glenn L. Martin company merged with American Marietta, a paint and aggregate firm, to form Martin Marietta. With the continued expansion of products, the Baltimore facility was designated to focus on the design of missiles and space products.

As the world entered the Space Age, Martin Marietta transitioned from winged wonders to celestial marvels. The company’s involvement in the Gemini Space Program, the second US human spaceflight program to fly, marked the company as a leading producer of space products. Contributing the launch vehicle for the lunar landing program, the company’s innovations meant that larger payloads could be placed in orbit than Atlas was capable of.

Diversification and Innovation (1970s-1990s):

The 1970s marked a pivotal change for Martin Marietta. As space programs shifted to newer facilities in Colorado and Florida, the company embarked on a new journey, focusing on cutting-edge composite technology. This dedication to research and development soon reaped rewards, with the company successfully producing large components for the Space Shuttle External Tank and the Los Angeles-class submarine X-24.

The 1980s witnessed further expansion, with Martin Marietta securing major contracts for the Navy’s MK 41 Vertical Launching System and expanding its product lines for anti-submarine warfare. This era also saw the company venturing into new arenas like environmental cleanup, utilizing its robotic technology expertise for a wider range of applications.

A New Era Dawns (1990s-Present)

The 1990s ushered in a period of transformation. While the end of the Cold War saw a major consolidation of defense assets, the company continued to thrive as a market leader. Martin Marietta entered into a landmark partnership with Pratt & Whitney for the new all-composite 4168 thrust reverser program, cementing its position as a leader in engine nacelle technology.

In 1995 Martin Marietta and the Lockheed Company announced a “merger of equals”, making the newly named Lockheed Martin one of the largest aerospace, defense, and technology companies in the world. Then, in 1977, Lockheed Martin turned over some of its business to General Electric (GE), including the operations at Middle River.

In 1998, the facility established a new identity as Middle River Aircraft Systems (MRAS), a wholly owned subsidiary of GE. MRAS continued to specialize in composite technology cementing them as leading manufacturers of engine nacelles, thrust reverser systems and complex aerostructures for military and commercial aircraft.

This 2000s saw the rise of collaborative ventures like the Nexcelle joint venture, capturing major wins with nacelle offerings for the COMAC C919 and the Passport 20 engine for the Bombardier Global 7000. MRAS’ success only continued throughout the year as the company signed contracts for the A320neo, CFM LEAP-1A and C919.

But the success of MRAS did not stop at its technology, but the company invested in its people through the HealthAhead initiative and the Collaborative Work System. Encouraging health lifestyles and an open and collaborative workplace, these efforts demonstrate the company’s dedication to its people.

In 2019, MRAS was acquired by ST Engineering and rebranded as Middle River Aerostructure Systems, to better reflect the diverse product offerings of the company. Since, the company has embarked on a new chapter of growth, leveraging the resources of its parent company to further build upon its business in nacelles and aerostructures. MRAS continues to be a world leading expert in the use of composite materials in the aerospace field.