Engineering Solutions

MRAS is a global leader in engineering solutions for nacelles and aerostructures, delivering exceptional expertise from initial concept development to fielded product support. With a comprehensive range of capabilities and a deep-rooted commitment to innovation, MRAS partners with aerospace OEMs and Tier 1 suppliers to address their most complex engineering challenges.

Design-to-Cost Excellence

MRAS’s full-scope capabilities, spanning product development to series production, enable a systematic design-to-cost approach that optimizes product performance while minimizing costs. The company’s design philosophy embraces “cost as a design requirement,” ensuring that every aspect of the product is evaluated for its impact on cost-effectiveness. Combining this philosophy with MRAS’s expertise in both metallic and composite nacelle components, the company consistently delivers solutions that exceed expectations.

Leveraging the Lean Lab for Innovation

MRAS’s Lean Lab serves as a hub of innovation, supporting technology development programs for the company’s engineering team and its partners. The lab complements the engineering design community by providing materials certification and qualification services, ensuring compliance with FAA conformity.

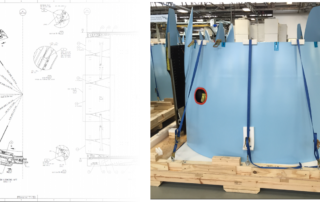

As an integral part of MRAS’s engineering organization, the Lean Lab plays a crucial role in the development and certification of new designs. The lab builds and tests subcomponents and structures, enabling evaluations at reduced scales and subsequent scale-up to full-size components. The lab also possesses the expertise to construct its own tooling for specialized testing, including subcomponent-level and reduced-scale testing with advanced measurement instrumentation.

Backing this robust testing capability are MRAS project engineers and manufacturing technicians who work closely with the engineering team to define and create project plans. Together, they form a collaborative alliance that drives innovation and ensures the success of MRAS’s engineering projects.

A One-Stop Materials Solution

The Lean Lab’s agility extends beyond testing, providing “one-stop” materials solutions through MRAS’s own materials properties database. This comprehensive database enables MRAS to meet a wide range of requirements, from material selection and design analysis to testing, qualification, certification, and production.

Unparalleled Engineering Expertise

MRAS’s engineering team boasts a wealth of experience in integration, design, testing, flight test support, and certification. Specialized expertise includes bird strike and lightning strike test and analysis correlation, as well as the definition and validation of anti-icing and fire protection features.

The team possesses in-depth knowledge of state-of-the-art design and analysis tools, enabling MRAS to develop weight- and cost-optimized designs that meet the most stringent customer requirements. Key engineering competencies at MRAS include:

- Digital product assemblies

- Kinematic simulations

- Integrated composite design and manufacturing

- Static and dynamic structural analysis

- Impact analysis

- Computational fluid dynamics (CFD)

- Thermal management