Introduction

When a Boeing 787 thrust reverser for a Trent 1000 powered aircraft suffered extensive damage during transportation back to the US, the asset was rejected from the global rotables pool. With mounting lease penalties and no established repair pathway for this type of damage, the customer turned to ST Engineering MRAS to deliver a solution that had never been executed before.

As a Collins licensed and Boeing 787 nacelle certified MRO, MRAS was uniquely positioned to take on the challenge and restore the asset to full OEM pool standard.

Project Background

The thrust reverser had originally been removed as part of an aircraft on ground event. A replacement unit was leased from ST Engineering’s Stockholm operation to keep the aircraft flying.

During shipment back to the United States, the removed thrust reverser sustained severe transportation damage caused by its crate hardware impacting the structure. When it arrived, the unit was found to be unfit for return to the OEM rotables pool. The damage extended across most of the assembly and included:

- Latch and hinge beam damage at multiple locations.

- A bent and damaged centre torque box.

- A damaged electrical feedback sensor.

- Dented, gouged and disbonded Inner Fixed Structure panels.

- Upper and lower V blade damage.

- Damaged heat blankets.

The customer now faced escalating lease charges until the unit could be restored to OEM pool condition.

Challenges

This was not a standard repair programme. In fact, it was the first time a Trent 1000 thrust reverser had ever undergone this level of structural repair at any licensed MRO.

The challenges included:

- No proven global repair precedent for this level of Trent 1000 thrust reverser damage.

- OEM repair data that had not yet been field validated.

- Complex structural, electrical and thermal system damage across multiple sub-assemblies.

- OEM supplied parts that required upgrades after delivery, leading to rework and delays.

- The project required constant coordination with the OEM to resolve data gaps, validate procedures and approve part and process updates as the work progressed.

Innovative Solutions

MRAS worked in close partnership with the OEM to turn untested repair documentation into a fully validated repair and recertification pathway.

The team applied their deep nacelle expertise to:

- Validate, correct and refine OEM repair data in real time.

- Manage part upgrades and rework when unproven components were found unsuitable.

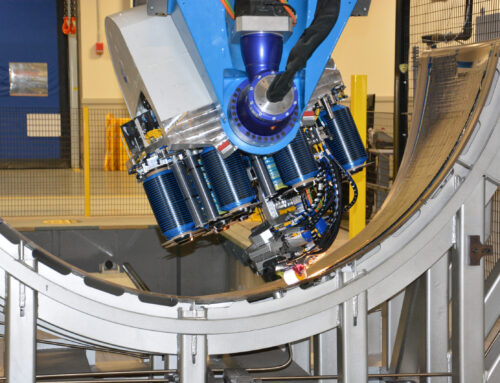

- Design and modify tooling to enable safe handling of the large thrust reverser structure.

One OEM lifting tool was modified by MRAS engineers to allow the thrust reverser to be rotated for installation and removal, enabling access to critical repair zones that would otherwise have been unreachable.

Weekly technical calls with the customer ensured transparency, alignment and rapid decision making as the project evolved.

Why ST Engineering MRAS?

MRAS was selected because it combined three critical capabilities:

- OEM licensing and certification as a Collins and Boeing 787 nacelle MRO

- Global ST Engineering support, including collaboration with the Stockholm nacelle team that initially supported the AOG event

- Engineering depth and tooling capability to create new repair pathways when none previously existed

This combination allowed MRAS to protect the customer from escalating lease costs while delivering a solution that met OEM rotables pool requirements.

Conclusion

Despite multiple unplanned technical hurdles, MRAS successfully restored and recertified the Trent 1000 thrust reverser to full OEM standards. The asset was accepted back into the global rotables pool, allowing the customer to close out the lease and avoid ongoing financial penalties.

The project established a new global benchmark for Trent 1000 thrust reverser repair, demonstrating MRAS’s ability to deliver first of type nacelle recovery programmes at OEM level.