By Tommy Acchione, Advanced Composite Material Leader, ST Engineering MRAS

JEC World continues to serve as the foremost global platform for the composites industry, and this year’s event in Paris was no exception. As a long-time attendee, I was pleased to see not only a strong turnout but also a continued drive across the sector to push technological boundaries. For ST Engineering MRAS, our presence at JEC World 2025 was both strategic and energising, allowing us to showcase our innovations, connect with global industry leaders, and explore partnerships focused on advancing composites manufacturing.

Strengthening Industry Presence

Our primary objective this year was to expand awareness of the ST Engineering brand within the global composites ecosystem. From OEMs to equipment providers and material innovators, JEC offers an unparalleled opportunity to build relationships and explore synergies. Thanks to an eye-catching booth and interactive displays, we saw noticeably increased visitor engagement, which directly reflected growing recognition of our capabilities and presence in the industry.

Showcasing ST Engineering MRAS Innovation

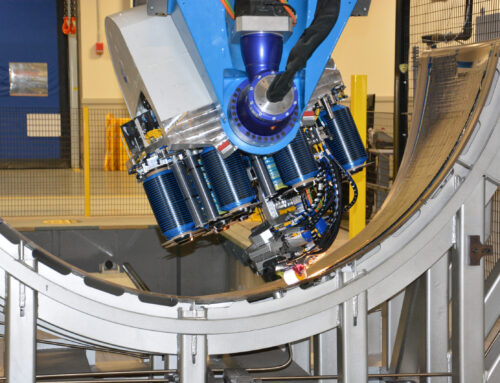

At the heart of our exhibit were several of our advanced manufacturing technologies, including our Automated Fiber Placement (AFP) processes, 3D-printed tooling, and post-bonding attachment techniques. These solutions demonstrate our commitment to innovation through precision, repeatability, and efficiency, key elements in meeting the growing demand for faster, more cost-effective composite part production.

Feedback from attendees, partners, and prospective collaborators was overwhelmingly positive, with many conversations centering around the practical application of our technologies in time-sensitive projects. Our focus on speed to market resonated strongly; something that was echoed by numerous stakeholders across the show floor.

Speed, 3D Printing, and the Push for Practicality

A key theme that stood out this year was the emphasis on rapid development and speed to market. Across the halls, it was clear that the composites sector is increasingly prioritising technologies that can shorten production cycles and enable just-in-time manufacturing. Nowhere was this more evident than in the proliferation of 3D printing innovations, particularly for tooling and on-demand part production.

Compared to previous years, there was a noticeable uptick in both machine builders and materials suppliers dedicated to additive manufacturing. The maturing of this space, and its integration into composite manufacturing environments, is something we at ST Engineering MRAS are watching closely. Our team had several productive conversations with developers of AFP machinery, ply placement systems, and 3D printing technologies, exploring ways to integrate these solutions into our operations to further benefit our customers.

Sustainability: A Work in Progress

While sustainability remains a prominent talking point, I observed a gap between aspiration and readiness. Many organisations are investing in sustainable materials, recycling processes, and waste-reduction technologies, but few are yet at the stage where these innovations can be scaled and implemented in real-world manufacturing environments.

There are promising signs, particularly around automation to reduce waste and additive technologies with more efficient material usage. However, no solution yet rivals the performance of carbon materials or energy-intensive curing processes when it comes to industrial production. We continue to monitor this space closely, with a view to adopting sustainable technologies as they mature.

Looking to the Future

JEC World always provides valuable perspective, and this year was no different. The key takeaway for us was a renewed focus on accelerating time to market through automation and digitally enabled production techniques. This aligns closely with our ongoing mission at ST Engineering MRAS: to deliver composite solutions that are not only high-performance but also developed with speed and efficiency in mind.

In the coming months, we’ll be deepening our conversations with several potential partners we met at JEC, particularly those innovating in 3D printing and automation. These collaborations have the potential to further streamline our internal processes and enhance the value we deliver to our customers.

As ever, our innovation journey continues, rooted in practical advancements, strong industry relationships, and a clear focus on the needs of our customers.