Introduction

ST Engineering MRAS delivered composites manufacturing excellence with the C919 Inlet project, showcasing end-to-end capabilities from design to certified part production.

Project Background

The C919 Inlet project required MRAS to design and produce nacelle components to customer specifications, including full certification, testing, and analysis. This was an opportunity to demonstrate its expertise in sustainable and composite manufacturing.

Challenges

- Developing lightweight, high-performance components.

- Meeting stringent certification requirements for aviation safety.

- Ensuring advanced acoustic and anti-icing performance.

Innovative Solutions

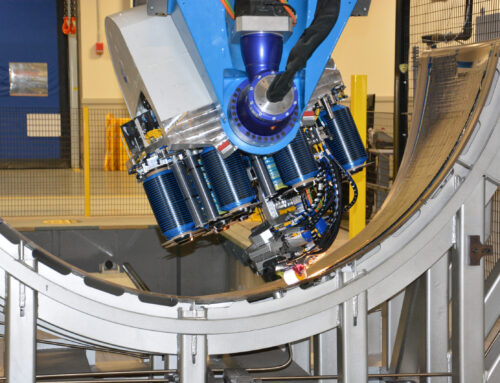

- Acoustically Treated One-Piece Inner Barrel: This is a tool-locked part with a seamless honeycomb core, using acoustically transparent core seaming

technology. - Directed Flow Swirl Nozzle: Enhances air circulation for anti-icing, improving safety and efficiency.

- In-House Testing: Icing, bird-strike, and lightning tests.

Why ST Engineering MRAS?

- Full in-house capabilities from design to certification.

- Advanced design features promoting sustainability.

- Proven track record of delivering certified aerospace components.

Conclusion

MRAS’s work on the C919 Inlet exemplifies composite manufacturing excellence. Its sustainable, high-performance components are now fully certified and flying.