Capabilities

MRAS: Leading the Way in Aerostructure Innovation

MRAS, we are at the forefront of aerospace and aerostructure innovation, delivering cutting-edge solutions that power the world’s most advanced aircraft and rockets. Our comprehensive capabilities in assembly, testing, and design, coupled with our expertise in composite materials and digital technologies, enable us to provide our customers with the highest quality aerostructure products.

MRAS’s comprehensive capabilities span a wide range of processes, including:

- Additive Manufacturing with 3D printers allows us to deliver tooling, machine components, and world-class flight hardware faster with a reduced carbon footprint.

- Advanced Composites Manufacturing, using autoclaves, automation and NDI equipment means we can manufacture composite and metallic structures from design to final fabrication, reducing both recurring and non-recurring costs.

- Automated Systems, including composite layup (AFP), multi-axis/multi-spindle machining and drilling, and robotic drill and fill fastening solutions, deliver world-class products to our valued customers.

- Non-Contact Metrology, which operates at high speed and high accuracy, allows us to drive toward the goal of zero defects.

- Advanced Assembly is achieved with proven hole to hole assembly techniques which reduces costs while delivering more accurate and faster-to-market hardware.

- Test and Certification delivers certified flight hardware achieved with advanced testing equipment, a skilled design team, and decades of experience.

Technology

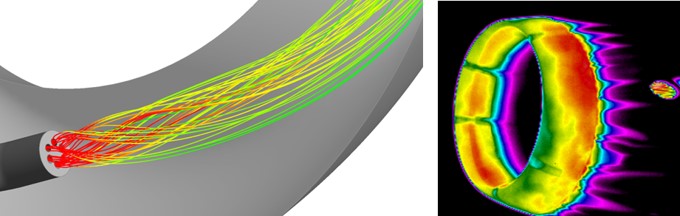

From initial concept development through fielded product support, MRAS offers a full range of engineering solutions for nacelles and aerostructures – applying its extensive experience in integration, design, testing, flight test support and certification. Nacelle component experience includes thrust reversers, fan cowl and inlet structures and engine build-up (EBU).

Production and Assembly

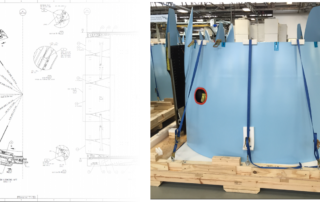

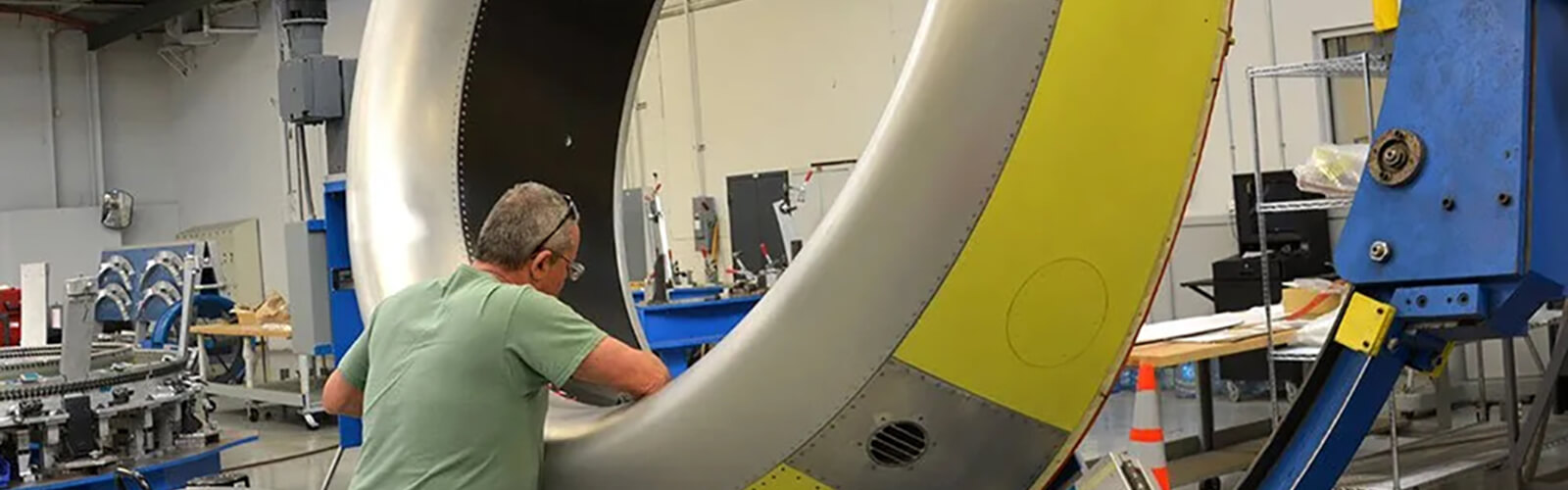

Unmatched Expertise in Assembly, Tooling, and Reverse Engineering: MRAS Assembly Group.

MRAS assembly group encompasses a comprehensive range of responsibilities, from tooling and process planning to shop floor support and ongoing production support. The group meticulously develops assembly methodologies, ensuring seamless process flow, efficient assembly line setups, and optimized assembly facilities.

FAA 145 Repair Station

MRAS is certified under the FAA/EASA Part 145 Repair Station Certificate, authorizing the company to perform MRO work on a variety of nacelle systems. This certification demonstrates MRAS's commitment to meeting the highest standards of quality and safety in the aviation industry.