Production and Assembly

Unmatched Expertise in Assembly, Tooling, and Reverse Engineering: MRAS Assembly Group.

Unmatched Expertise in Assembly, Tooling, and Reverse Engineering: MRAS Assembly Group.

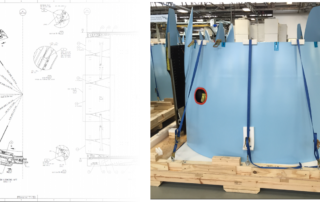

MRAS assembly group encompasses a comprehensive range of responsibilities, from tooling and process planning to shop floor support and ongoing production support. The group meticulously develops assembly methodologies, ensuring seamless process flow, efficient assembly line setups, and optimized assembly facilities.

MRAS’s assembly group embraces the latest digital technologies, revolutionizing laser and dimensional inspection, and reverse engineering practices. The V-Stars digital photogrammetric system seamlessly integrates with CAD data, enabling precise repeat measurements for tooling inspections and production process verification.

MRAS’s laser tracker system excels in high-accuracy, absolute-distance measurements, meticulously evaluating large parts, tools, and machine tools. The company utilizes Verisurf, CAM2, and Solids software for real-time identification and verification of feature locations, directly referencing CAD-released files. 3D design models serve as active participants in the build-up process, further enhancing precision and efficiency.

In line with MRAS’s “under one roof” approach, the assembly group collaborates closely with the company’s designers, ensuring optimal producibility for structures and components. The group also benefits from the resources of an in-house tool manufacturing center, ensuring the availability of specialized tooling for complex assembly operations.

MRAS’s expansive 2.0-million sq. ft. facility boasts 75,000 sq. ft. of high-bay assembly area, equipped with 3-ton cranes, and 90,000 sq. ft. of low-bay assembly areas, featuring 2-ton cranes. Both areas are powered by 90 psi. air and 460 Volt electrical power, ensuring ample support for demanding assembly processes.

MRAS’s assembly group extends its expertise to the company’s suppliers, providing guidance for part production and assistance in resolving technical or producibility issues. This proactive approach fosters strong partnerships and ensures the delivery of high-quality components.

Partner with MRAS for Unmatched Assembly Solutions

With its comprehensive assembly capabilities, innovative technologies, and unwavering commitment to quality, MRAS stands as a trusted partner for aerospace OEMs and Tier 1 suppliers. Contact MRAS today to experience the difference of unmatched expertise in assembly, tooling, and reverse engineering.