Technology

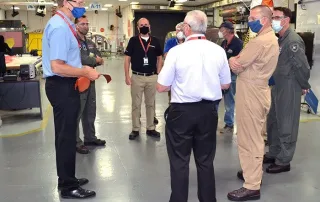

From initial concept development through fielded product support, MRAS offers a full range of engineering solutions for nacelles and aerostructures – applying its extensive experience in integration, design, testing, flight test support and certification. Nacelle component experience includes thrust reversers, fan cowl and inlet structures and engine build-up (EBU).

The MRAS engineering team possesses in-depth knowledge of state-of-the-art design and analysis tools to develop weight- and cost-optimized designs that meet customers’ challenging requirements, with such specialties as bird strike and lightning strike test and analysis correlation, as well as the definition and validation of anti-icing and fire protection.

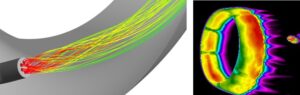

Key engineering competencies at MRAS include digital product assemblies, kinematic simulations, integrated composite design and manufacturing, static and dynamic structural analysis, impact analysis, computational fluid dynamics (CFD) and thermal management.

A Commitment to Innovation

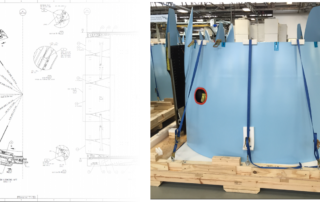

MRAS is at the forefront of inlet technology, continuously exploring innovative materials and designs to improve aerodynamic efficiency, noise reduction, and weight optimization. MRAS’s inlet feature a patented light weight Directed Flow Swirl Nozzle (DFN) to deliver anti-icing capability to the lip skin and prevent build up of ice during flight.

MRAS is committed to developing next-generation inlets that set new benchmarks for performance and sustainability.

MRAS offers a comprehensive range of inlet designs to suit diverse aircraft requirements:

- Advanced Composite Inlets: MRAS utilizes advanced composite materials like carbon fiber to produce lightweight, robust, inlets that enhance aerodynamic performance.

- Integrated Inlet Systems: MRAS provides integrated inlet systems that seamlessly integrate with the engine core, optimizing airflow and reducing noise emissions.