Introduction

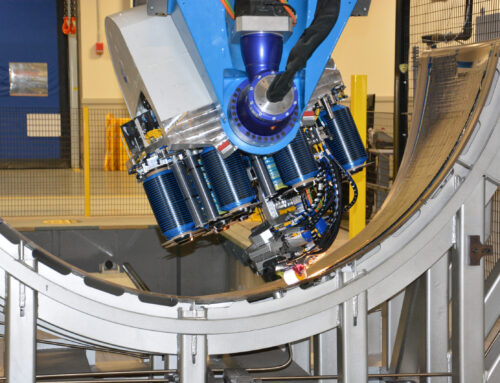

ST Engineering MRAS demonstrated its multi-material assembly capabilities through the Fuselage Panel Attachment Demonstrator, showcasing innovative attachment technologies and advanced manufacturing techniques.

Project Background

The demonstrator panel was designed to explore and validate various attachment methods. With four stringers, each bonded

differently, this project highlighted MRAS’s ability to innovate and adapt in aerospace manufacturing.

Challenges

- Need to showcase different attachment technologies.

- Integration of advanced and experimental materials.

- Ensuring structural integrity with varied bonding methods.

Innovative Solutions

Advanced Technologies:

- Co-molded with Epoxy Film Adhesive: Industry standard bonding method.

Mechanically Fastened with Titanium Fasteners: Traditional aerospace technique.

Structural Paste Adhesive: New-to-market technology for enhanced structural performance.

Composite Fasteners: Innovative solution addressing supply chain challenges and promoting lightweight, high-performance materials. - Advanced fiber placement technology was used for stringer

production, and thermoplastic technology was explored for future aerospace applications.

Why ST Engineering MRAS?

- Expertise in assembling multi-material parts.

- Commitment to sustainable manufacturing practices.

- Ability to drive innovation in lightweight, high-performance materials.

Conclusion

MRAS successfully demonstrated advanced attachment technologies, paving the way for future innovations in aerospace

manufacturing.