Introduction

When a major North American airline faced a critical issue with a severely damaged Boeing 787 GEnx-1B inlet following a ramp accident, they turned to ST Engineering MRAS (MRAS) for their unmatched expertise in Maintenance, Repair, and Overhaul (MRO) services. With significant deformation and corrosion, the damaged inlet required a skilled team capable of handling complex repairs while minimizing downtime.

Project Background

A ground handling accident damaged a B787 inlet, significantly deforming the lipskin. With corrosion spreading through key segments and various levels of structural damage, the airline needed an OEM-licensed MRO with immediate access to exchange units and a proven ability to handle the intricate task of restoring the inlet.

Challenges

The damaged inlet presented a number of specific challenges, each requiring a specialized solution:

1. The lower lipskin was severely deformed, and corrosion affected the remaining segments.

2. The design of the lipskin limited access to internal fasteners, making removal and replacement challenging.

3. A large number of blind fasteners needed to be removed without enlarging OEM-designed holes.

4. The entire lipskin assembly had to be removed without causing damage to nearby components.

Innovative Solutions

MRAS addressed each of these challenges with innovative techniques:

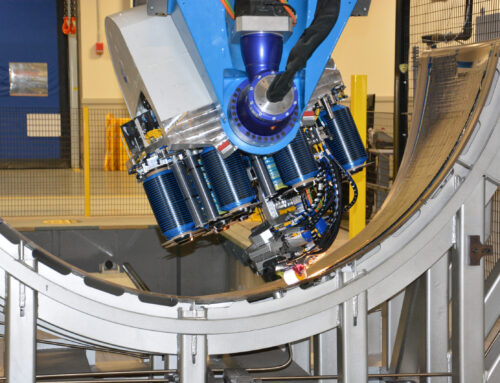

• The team designed specialized in-house tooling to properly position and inspect the inlet, ensuring precise maneuverability for detailed assessments.

• Leveraging its global expertise in nacelle repair, the team developed a unique method for accessing internal fasteners without compromising the structure.

• MRAS utilized industry-leading technology to remove blind fasteners, avoiding the risk of enlarging OEM-designed holes.

• The team designed custom tooling that safely removed the lipskin assembly without damaging adjacent structures.

Why MRAS?

MRAS stood out as the ideal partner for this complex project due to several key factors:

• With over 95 years of aerospace industry leadership and a team of 1,000+ skilled professionals, MRAS offers an unparalleled MRO experience.

• As one of the few MROs globally licensed by the OEM, MRAS had the tools, expertise, and access to 787 OEM manuals & spare parts necessary to complete the repair.

• MRAS’ strategic location near major transportation hubs and ownership of exchange assets allowed it to respond quickly and minimize the airline’s downtime.

Conclusion

MRAS’s commitment to precision and innovation ensured the successful restoration of the Boeing 787 GEnx-1B inlet, providing the customer with a high-quality repair and peace of mind. With a combination of cutting-edge technology, OEM designed & custom tooling, and decades of experience, MRAS continues to set the benchmark for excellence in MRO services.