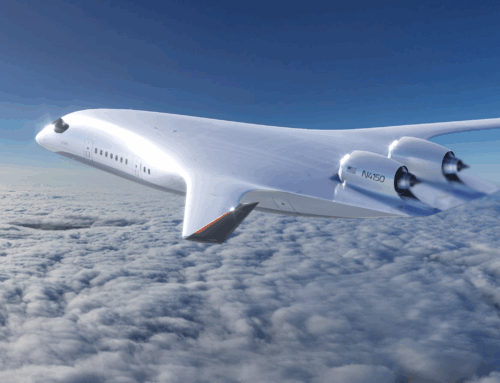

In commercial aviation, time is money, and nowhere is that more apparent than during an AOG (Aircraft on Ground) event. A grounded aircraft can cost operators tens of thousands of dollars per hour. This is without taking into account the disruption to schedules, crew rotations, and passenger experience. For fleet managers and maintenance planners, the goal is therefore simple: keep aircraft in service, safely and efficiently.

One of the most powerful tools to achieve this is a robust nacelle rotables exchange and lease program. ST Engineering MRAS leads the way with OEM-level expertise, global inventory support, and 24/7 AOG responsiveness.

Why Nacelle Rotables Are Essential

“Nacelle rotables” are high-value nacelle and thrust reverser components, such as inlets, fan cowls, and thrust reversers, that can be removed, repaired, and returned to service multiple times. Unlike other expendable parts, rotables have a full traceable life cycle and are serialized for complete maintenance history tracking.

Maintaining a well-managed rotable inventory provides operators with four key benefits:

- Cost efficiency – Access to a shared pool of serviceable parts covering B787, A320neo LEAP-1A, CF6-80C2, B737, and more eliminates the need to purchase new components every time, reduces capital tied up in spare inventory, and keeps repair costs predictable.

- Minimal downtime – Exchange programs allow airlines to immediately swap a damaged unit for a ready-to-install component, avoiding lengthy overhaul turnaround times.

- Safety and compliance – All parts are serviced at certified facilities and delivered with airworthiness documentation, ensuring regulatory compliance and full traceability.

- Operational flexibility – Rotable pools allow airlines to adapt to fluctuating maintenance demand, fleet growth, or changing operational requirements without overstocking.

The Repair or Replace Decision

When a nacelle component is damaged, fleet operators face the crucial decision, should it be repaired or replaced.

- Repair is often more cost-effective when the part can be restored within OEM-approved limits and downtime is manageable.

- Replace or exchange is preferred when time is critical, damage is extensive, or repairs exceed economic thresholds.

MRAS supports this decision-making process with engineering expertise, cost modelling, and real-time availability data. Their approach ensures operators can weigh turnaround time against cost, selecting the best solution for their operation.

An exchange solution often delivers the best balance, keeping the aircraft flying while the original unit is repaired and reintroduced to the pool. MRAS can complete exchanges within 24 hours, minimizing costly downtime and getting aircraft back into service fast.

Technical Expertise: Why MRAS Is Different

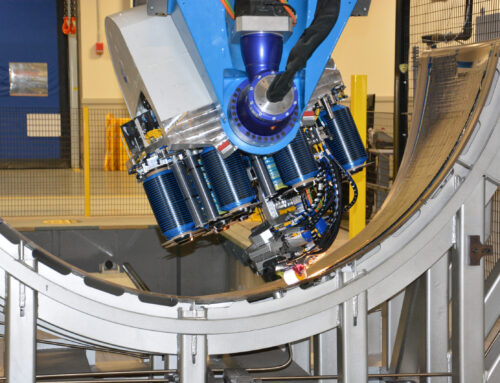

Modern nacelle systems are complex. They combine advanced composite structures, acoustic liners, actuation systems, and thermal management features, designed to precise aerodynamic tolerances. Maintaining or repairing these systems requires deep design knowledge and access to proprietary repair data.

Modern nacelle systems are complex. They combine advanced composite structures, acoustic liners, actuation systems, and thermal management features, designed to precise aerodynamic tolerances. Maintaining or repairing these systems requires deep design knowledge and access to proprietary repair data.

MRAS is not just an MRO provider; it is an OEM nacelle designer and manufacturer with over 95 years of heritage, and one of a very small group of globally licensed OEMs with full repair capability for B787 and A320neo LEAP-1A nacelles.

This means:

- Repairs are performed to OEM standards with full engineering oversight.

- Access to the latest service bulletins, design changes, and materials data ensures repairs meet current specifications.

- Turnaround times are optimized by integrating repair planning with rotable inventory management.

This OEM pedigree gives operators peace of mind that every rotable unit meets the highest quality and safety standards.

Lifecycle and Inventory Management

A nacelle component’s lifecycle is long, but its service intervals are demanding. MRAS provides end-to-end support from Entry Into Service through end-of-life, helping operators:

- Plan rotable coverage based on fleet size and utilization.

- Avoid overstocking or understocking spares.

- Ensure availability of components for mature platforms where new production may be limited.

MRAS is continually evaluating additional nacelle platforms to meet growing demand and support the expanding fleets of its customers in the Americas.

Sustainability: Extending Life, Reducing Waste

Aviation is under increasing pressure to reduce its environmental footprint, not just in flight but across the supply chain. Rotables are a prime example of circular economy in action.

Every time a nacelle component is repaired and returned to service, it avoids the emissions, energy use, and raw material consumption associated with manufacturing a new part. MRAS’s advanced composite and metal-bonding repair techniques maximize recoverability and minimize scrap, supporting both cost savings and sustainability goals.

For those airlines working toward net-zero, rotables can be incorporated into their maintenance strategy as a practical step toward more responsible operations.

Case in Point: Rapid AOG Recovery

Consider a fleet operator experiencing ground damage to a B787 thrust reverser. Without access to a replacement, the aircraft could remain grounded for weeks while the component is shipped, repaired, and returned.

Every time MRAS performs a nacelle exchange, it saves operators significant downtime during AOG events. By providing ready-to-install components within 24 hours, MRAS helps operators avoid weeks of disruption and the associated financial impact. In many cases, an exchange can save millions of dollars and months of lead time compared with purchasing new nacelle components.

Why Choose MRAS for Rotables Support

MRAS offers a complete nacelle support solution, combining:

- Extensive rotable inventory covering B787 GEnx & T1000, LEAP-1A, CF6-80C2, B737, and more.

- FAA and EASA Part 145-certified MRO capabilities, plus AS9100, AS9110C, and NADCAP approvals.

- 24/7 AOG hotline for rapid response worldwide.

- OEM-level technical knowledge and direct access to proprietary repair data.

- Sustainability-focused repair processes that extend component life and reduce waste.

This integrated approach delivers not just parts, but also peace of mind. This ensures that operators can keep fleets flying safely, efficiently, and sustainably.

With this combination of global coverage, OEM expertise, and rapid response, MRAS delivers not just parts, but a reliable partnership that protects operators’ schedules, budgets, and sustainability goals.

Take the Next Step

Whether you are planning fleet expansion, facing an AOG event, or rethinking your spare parts strategy, MRAS can help you design a rotable program that meets your cost, availability, and sustainability goals.

Contact the MRAS MRO team today to discuss your nacelle rotable strategy.