Complex Structures

Mastering Aerospace Complexity: MRAS Expertise in Complex Structures

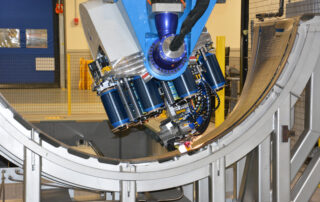

MRAS is a recognized leader in the design, development, and manufacturing of complex aerospace structures. With over nine decades of experience, MRAS has established a reputation for innovation, quality, and reliability. The company’s team of highly skilled engineers and technicians leverages their in-depth knowledge of advanced materials and manufacturing technologies to deliver exceptional products that meet the stringent requirements of the aerospace industry.

Fabrication and Assembly of complex metallic and composite structures

- Complex metal and composite structures for the Lockheed Martin P-3 Orion, an anti-submarine and maritime surveillance aircraft. These structures supported the Flight Control Surface components, including the Horizontal Stabilizers and Leading-Edge assembly, as well as Fuselage components, such as Longerons. MRAS technology and manufacturing knowhow were critical to the aircraft’s life extension program.

- Major structural components for the Wings of the Bell V-22 Osprey Vertical Take-Off and Landing (VTOL) military rotorcraft. The company specifically worked on the Flaperon, Flap Seal, and Fixed Trailing Edge.

- Antenna structures for the Boeing E-7 Airborne Early Warning and Control (AEW&C) Wedgetail aircraft.

- The Nose Cap and Fairing for Lockheed Martin Trident D-5 ballistic missile components.

- The Wide Aperture Array (WAA) of the nuclear-powered submarines in military service with the US Navy.

- Structural components and assemblies of over 10,000 Boeing CH-47 Chinook and Apache military rotorcrafts.

- Production and Aftermarket support for the Exhaust Nozzles of the Lockheed Martin C130 Hercules military transport aircraft.

- Skins, Stringers, and other structural components of multiple rocket systems supporting commercial and military space missions.

New Product Line Startup Support

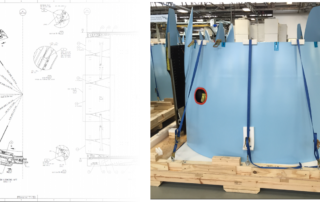

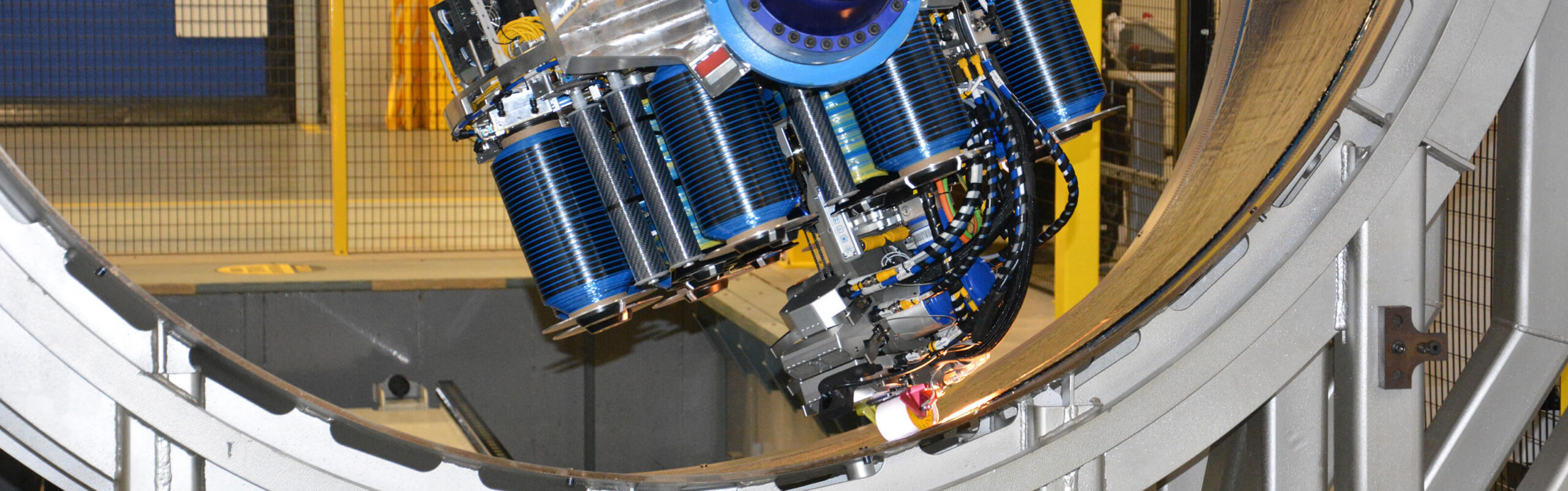

MRAS assists in the start-up of new product lines, providing guidance and support throughout the development process. The engine fan containment case for the Boeing 777X aircraft is one of many examples where MRAS innovation excellence and in-house expertise regarding composite material systems and manufacturing were essential to the successful execution of the development program including low-rate initial production (LRIP).

A Trusted Partner for Complex Aerospace Structure Solutions

MRAS stands as a trusted aerostructures partner, committed to providing high-quality, cost-effective solutions to its customers. The company’s expertise, capabilities, and proven track record make it an ideal partner for any aerostructures project.

Our Expertise in Space Structures

MRAS engineers and technicians also possess extensive knowledge in creating critical components for spacecraft and launch vehicles including payload fairings, spacecraft truss structures, , satellite antenna structures, and spacecraft adapters and interfaces.

MRAS’s Commitment to Complex Structure Solutions

MRAS is committed to tackling the most complex aerospace structures, collaborating with its customers to understand their specific requirements and deliver innovative solutions that exceed expectations. The company provides tailored design solutions, utilizes advanced manufacturing capabilities, and subject its products to rigorous testing and validation procedures to ensure they meet the stringent safety and performance requirements of the aerospace industry.

MRAS: Your Trusted Partner for Aerospace Complexity

With its proven expertise, comprehensive capabilities, and unwavering commitment to quality, MRAS is the partner you can rely on to deliver high-performance solutions for your most challenging aerospace projects. Partner with MRAS today and navigate the complexities of aerospace engineering with confidence.