Introduction

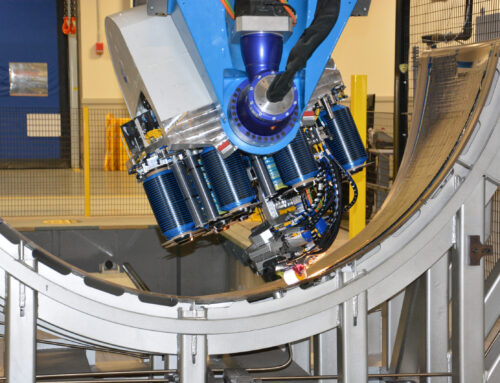

ST Engineering MRAS showcased its agility in aerospace manufacturing by reducing the time from concept to part production to under three months. This rapid turnaround was achieved utilizing in-house capabilities, advanced technologies, and composite manufacturing excellence.

Project Background

The customer needed faster solutions, and when external quick-turn tools were unavailable, MRAS innovated internally.

Challenges

- Aggressive project timelines demanding rapid turnaround.

- Lack of quick-turn tooling options from external suppliers.

- Close part tolerance expectations.

Innovative Solutions

Advanced Technologies:

- Additive Manufacturing: In-sourced equipment accelerated the process, reducing tooling costs and improving time-to-market.

- Digital Thread: In-house capabilities enabled rapid design iterations through a “digital tooling stream,” providing complete control over tooling changes.

Composite Manufacturing:

- Customer-specified prepreg for part production.

- Additive manufacturing materials selected for autoclave capability.

- The agile development method shortened development time, reduced costs, and allowed for rapid adjustments to meet customer requirements.

Why ST Engineering MRAS?

- In-house capabilities ensure a deep understanding of process limitations and requirements.

- Ability to meet high tolerance expectations even with 3D-printed tooling.

- Responsive to last-minute certification changes with minimal cost impact.

Conclusion

MRAS redefined aerospace development timelines, challenging the industry standard of 18 months with a rapid, cost-effective process. This is agile composite manufacturing excellence at its best.