As the aerospace industry moves toward lighter and more efficient propulsion systems, nacelle design has become a focal point for innovation. While many manufacturers are still exploring new materials and architectures, ST Engineering MRAS is already operating in a new phase of industrialisation defined by automation, digital integration, and validated production systems.

As the aerospace industry moves toward lighter and more efficient propulsion systems, nacelle design has become a focal point for innovation. While many manufacturers are still exploring new materials and architectures, ST Engineering MRAS is already operating in a new phase of industrialisation defined by automation, digital integration, and validated production systems.

For decades, nacelle development has followed a pattern of incremental improvement, characterized by lighter structures, quieter operation, and improved maintainability. As propulsion technologies evolve and sustainability pressures intensify, the focus is shifting from component optimisation to system-level transformation. The nacelle is no longer just a housing for the engine but an active enabler of aerodynamic, acoustic, and thermal performance, and a central component in the digital manufacturing ecosystem.

While several OEMs are advancing thermoplastic composites and electric actuation systems, few have achieved the industrial maturity, digital continuity, and automation capability already embedded within ST Engineering MRAS operations.

“At ST Engineering MRAS, we see it as our mission to develop and bring technologies forward that enable our customers to meet the performance needs of future platforms,” says Mitch Smith, Vice President of Operations and Director of Technology and Process Engineering. “Our investment in automation and the digital thread ensures every nacelle we build is on-time and on-cost with highest quality standards.”

Engineering Beyond the Material Revolution

Advanced materials remain central to nacelle performance, but ST Engineering MRAS’s strength lies in how those materials are engineered, industrialised, and certified. With decades of experience in composite structures, the company fabricates nacelle components using a wide range of resin systems and carbon fibre forms from leading suppliers.

Its manufacturing and assembly expertise spans across multiple aerostructures and Nacelle components including fan cowls, inlets, and thrust reverser structures in service across multiple commercial and defence programs. Engineering teams translate aerodynamic and thermal performance requirements into optimised composite structures, balancing structural efficiency with lightning protection, fire resistance, and bird-strike tolerance.

This integration of design and production disciplines enables ST Engineering MRAS to achieve design-for-manufacture maturity rarely matched in the nacelle sector. Rather than focusing on laboratory demonstrators, the company develops repeatable, rate-capable processes that comply with certification standards from the FAA, EASA, Transport Canada, and CAAC for strength, fatigue, and damage tolerance.

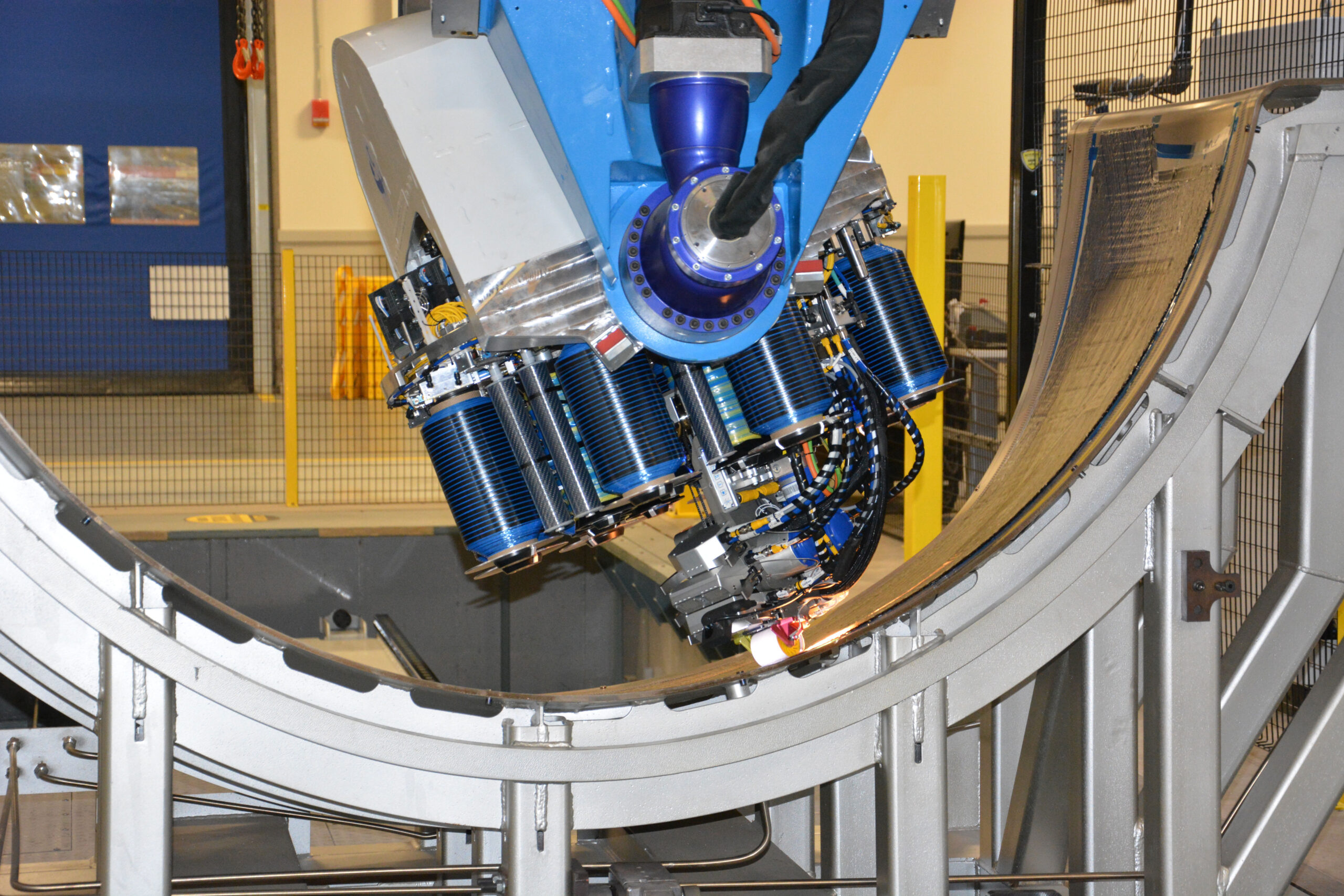

Automation as an Engineering Enabler

A clear engineering principle guides ST Engineering MRAS’s approach to manufacturing transformation: automation is not simply about speed, but about precision, repeatability, and quality assurance.

At the company’s 1.9-million-square-foot Baltimore facility, extensive clean-room lay-up and assembly areas operate as part of an integrated digital ecosystem.

The Automated Fibre Placement (AFP) systems at ST Engineering MRAS, build product and simultaneously inspect materials ensuring process parameters are monitored in real time throughout the component build. Expanding automation to key processes, tool cleaning, acoustic drilling and robotic assembly, achieves micron-level precision and a consistent product.

“We’ve built an environment where automation and human expertise work in concert,” explains Smith. “Our technicians operate within a digital framework that connects design, production, and inspection.”

Automation extends beyond the production floor. Robots perform scheduled facility inspections using acoustic, thermal, and LiDAR sensors to assess equipment condition and detect deviations. This predictive monitoring supports process reliability and reinforces MRAS’s operational resilience.

The Digital Thread in Action

The defining strength of ST Engineering MRAS lies in the digital thread being developed. Creating a unified data pathway linking engineering design, manufacturing execution, testing, and lifecycle support, offers significant benefits to end users.

The company uses common control systems across ten autoclaves, multiple ovens, and CNC machining centres, enabling centralised monitoring and automatic documentation of every cure cycle and machining event. When combined with digital inspection and configuration management, these systems create an authoritative digital record for every component.

This data continuity accelerates certification, strengthens traceability, and provides critical feedback for maintenance and sustainment planning. For high-rate nacelle programs that require on-wing reliability and predictable performance, such digital integration offers a competitive and operational advantage.

“The aerospace market increasingly recognises that a digital thread is as transformative as any new material,” says Sugato Bhattacharjee, Head of Strategy and Business Development. “The ability to link design intent to production data, inspection, and service information defines the next generation of supply chain readiness. That is the foundation of the ST Engineering MRAS experience.”

Proven Maturity Across Programs

ST Engineering MRAS’s manufacturing maturity is reflected in its extensive portfolio, covering both legacy and emerging platforms. The company designs and produces nacelle systems and complex structures for Boeing 767, 747, and 777X, Airbus A320neo, Lockheed Martin C-5 and C-130J and Bombardier Global 7500. It also engineers high-performance composite components for Archer Aviation and others.

The ongoing Jet Zero demonstrator exhaust nozzle project exemplifies ST Engineering MRAS’s ability to support the propulsion architectures of the future. The program integrates composite materials, advanced bonding processes, and automated assembly techniques to produce a lightweight, thermally resilient structure capable of meeting next-generation aerodynamic and thermal demands.

Certification is embedded in every engineering activity. ST Engineering MRAS conducts structural, fatigue, and bird-strike testing both in-house and through accredited test centres, maintaining familiarity with Part 25 and Part 33 requirements.

This extensive body of certified work reflects an industrial readiness that few nacelle suppliers can match. While others focus on proof-of-concept demonstrators, ST Engineering MRAS’s digitally linked production system already manufactures qualified nacelle structures at scale.

Sustainability and Process Efficiency

Automation and digital integration at ST Engineering MRAS are also central to the company’s sustainability and efficiency objectives. By minimizing manual rework, optimizing material utilization, and improving cure precision, ST Engineering MRAS reduces energy consumption and waste throughout the production lifecycle.

Its phosphoric acid anodising line and in-house bond primer application process are NADCAP-accredited, ensuring both corrosion resistance and environmental compliance. Similarly, the use of digital monitoring in ST Engineering MRAS’s paint facilities allows precise control of emissions, curing cycles, and material usage.

“Efficiency is driven into every layer of our operations,” notes Smith. “When each process operates within a digitally connected system. From fibre placement to final paint, you not only improve throughput but achieve measurable sustainability gains. It’s a disciplined, data-driven approach to manufacturing performance.”

Building the Next-Generation Nacelle

ST Engineering MRAS views the nacelle as a system enabler for future propulsion technologies, rather than a passive structure. Current R&D efforts explore new composite architectures, improved acoustic liners, and integrated electrical and thermal management systems designed to align with next-generation engines and hybrid-electric platforms.

Bhattacharjee emphasises that this systems-level view is essential as propulsion concepts become more distributed and more integrated with the airframe. “The nacelle of the future will incorporate sensing, electrical actuation, and thermal management systems within an optimised composite framework,” he explains. “It will interact with digital twins and predictive maintenance tools, creating a continuous data exchange between design, manufacturing, and operation. That’s the trajectory we’re already engineering toward.”

This strategic focus on readiness, not only for the next program but for the next technological paradigm, positions ST Engineering MRAS to adapt quickly to the needs of hydrogen combustion, hybrid-electric, and ultra-high bypass engine architectures.

Collaboration and Industry Alignment

As OEMs and tier-one suppliers pursue aggressive performance and sustainability targets, ST Engineering MRAS’s model demonstrates how industrial capability and innovation can progress in parallel. The company’s engineering heritage in nacelle and complex structures, combined with continuous investment in process automation and digital manufacturing, provides a foundation for future collaboration.

“We don’t innovate in isolation,” Bhattacharjee says. “Our development programs are aligned with customer roadmaps and validated within live production environments. The objective is not experimentation for its own sake but engineering advancement that’s immediately producible at scale and rate.”

Across its global partnerships, ST Engineering MRAS’s facilities serve as working demonstrations of what a digitally connected aerospace factory can achieve; where fibre placement, bonding, machining, and inspection are orchestrated by data continuity rather than manual intervention.

Conclusion

The nacelle sector is entering a defining era. Weight reduction, noise control, and electrification remain priorities, but the real step change lies in how these goals are industrialised. With its automation infrastructure, digital thread, and validated production systems, ST Engineering MRAS is not just adapting to that change, it is leading it.

“Automation and data integration are redefining how we design and build complex structures,” says Smith. “At ST Engineering MRAS, they’re already part of daily production.”

As propulsion system developers seek partners capable of turning advanced concepts into certified, scalable products, ST Engineering MRAS provides a clear example of how digital and manufacturing excellence combine to shape the nacelles and aerostructures of the future.